COMPANY PROFILE

At Shantou City YaPeiNi Knitting Underwear Factory, we specialize in designing and manufacturing innovative and functional lingerie that blends comfort, confidence, and performance. Our core product lines include body shapers, period underwear, seamless panties, and bras — all crafted with premium materials and precision tailoring.

With a commitment to empowering women through smart design and sustainable practices, we offer solutions for everyday wear, active lifestyles, and special needs like menstrual protection. Partner with us for private labeling, OEM/ODM services, and full support from design to production.

1300㎡

FACTORY AREAS

1568+

SELF-DESIGNED

400+

TECHNICAL STAFF

40+

COUNTRIES SOLD

Our Factory

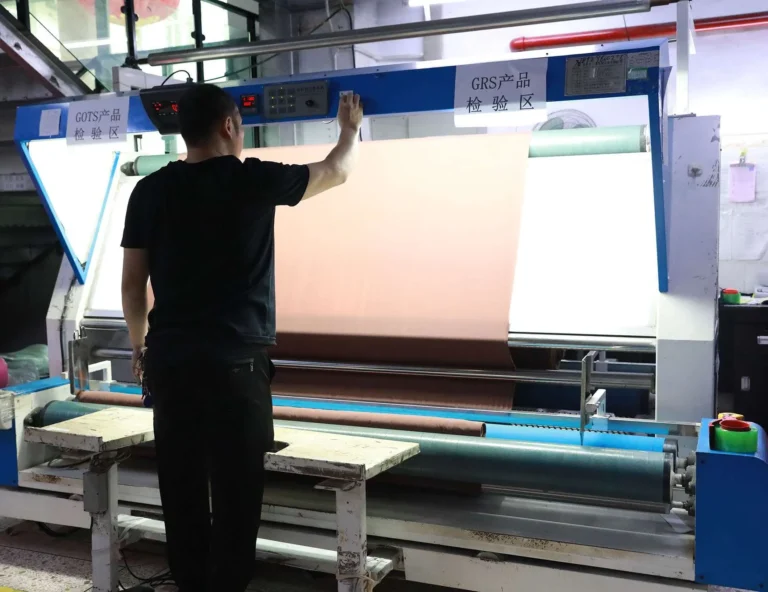

Fabric Inspection

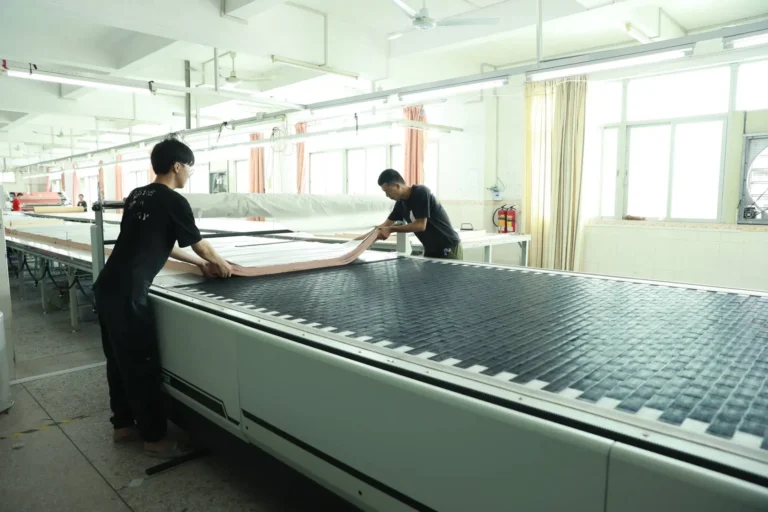

Cutting Line

Production Line

Laser Cut Line

Sewing Line

Mold Cup Line

Quality Inspection

Warehouses

Manufacturing Process

We specialize in custom underwear manufacturing, tailored to your brand.

With our own production facility and a trusted network of textile partners, we offer end-to-end customization for shapewear, period underwear, seamless panties, and bras. From fabric sourcing and pattern design to private labeling and packaging, every order is crafted to match your unique vision — with flexibility, speed, and uncompromised quality.

- Self-own Factory with 20+ Years Experience

- 80+ Upstream & Downstream Partners

- 100+ Machines for Various Processes

Sample Room

Review materials, trims, and styles to confirm product direction.

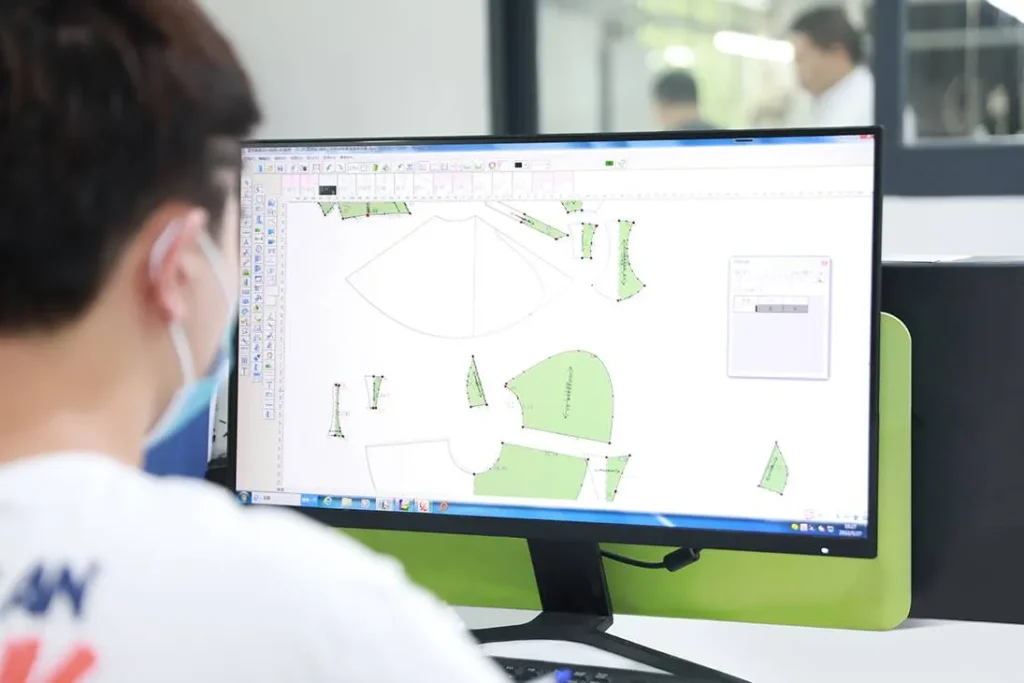

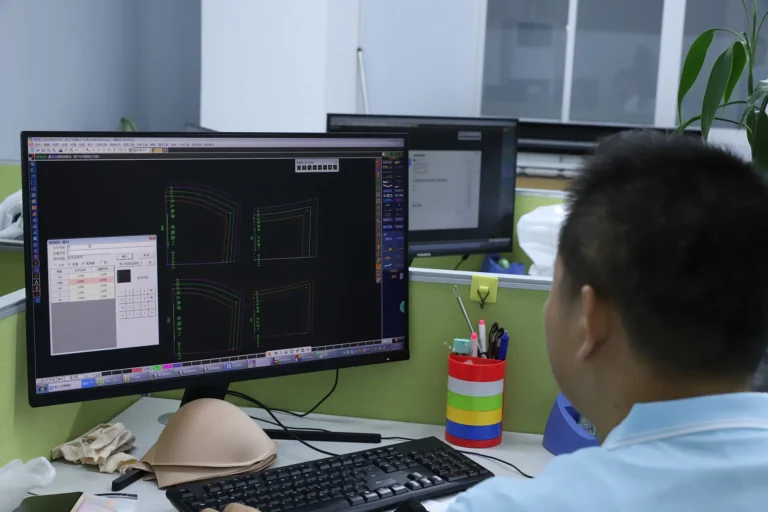

Digital Pattern Making

Use CAD software to create precise digital paper patterns.

Plotter for Pattern

Print paper patterns accurately for cutting preparation.

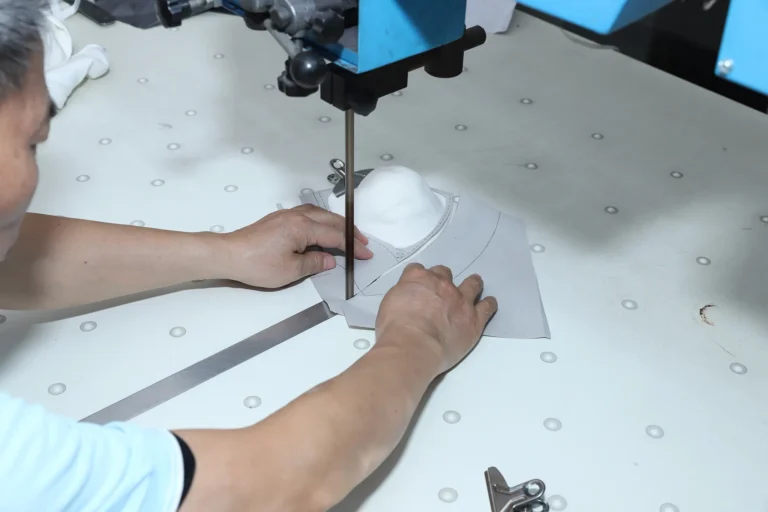

Manual Cutting

Cut samples' fabric layers by machine using paper markers.

Manual Cutting

Cut samples' fabric layers by hand using paper markers.

Sample Sewing

Sew samples based on design for approval or fitting.

Fitting on Mannequin

Fit sample on dress form to check silhouette and adjust.

Fabric Inspection

Inspect fabric rolls for color, quality, and surface defects.

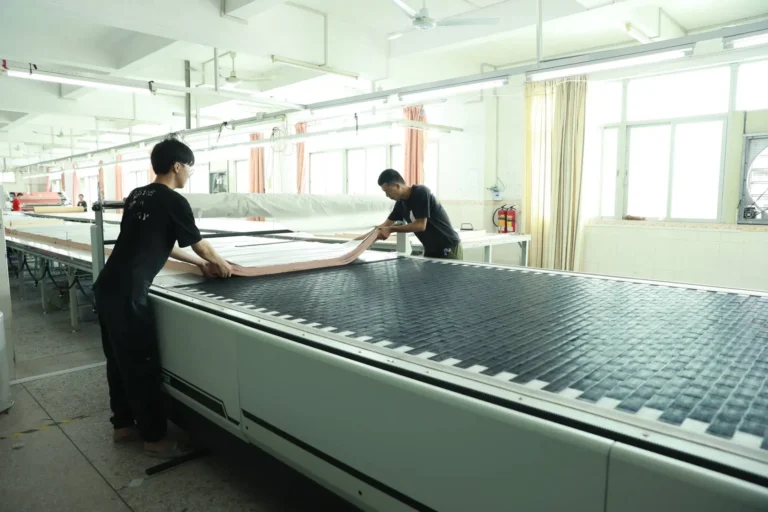

Cutting Table

Cut fabric layers by machine using paper markers.

Production Line

Mass produce garments with skilled workers.

Production Line

Mass produce garments with skilled workers.

Production Line

Mass produce garments with skilled workers.

QC Inspection

Check size, stitching, fabric quality, and label details.

Needle Detection

Detect metal or broken needles to meet safety standards.

Packing Line

Fold, bag, label and pack according to order details.

Warehouse

Store finished goods and prepare for timely shipment.

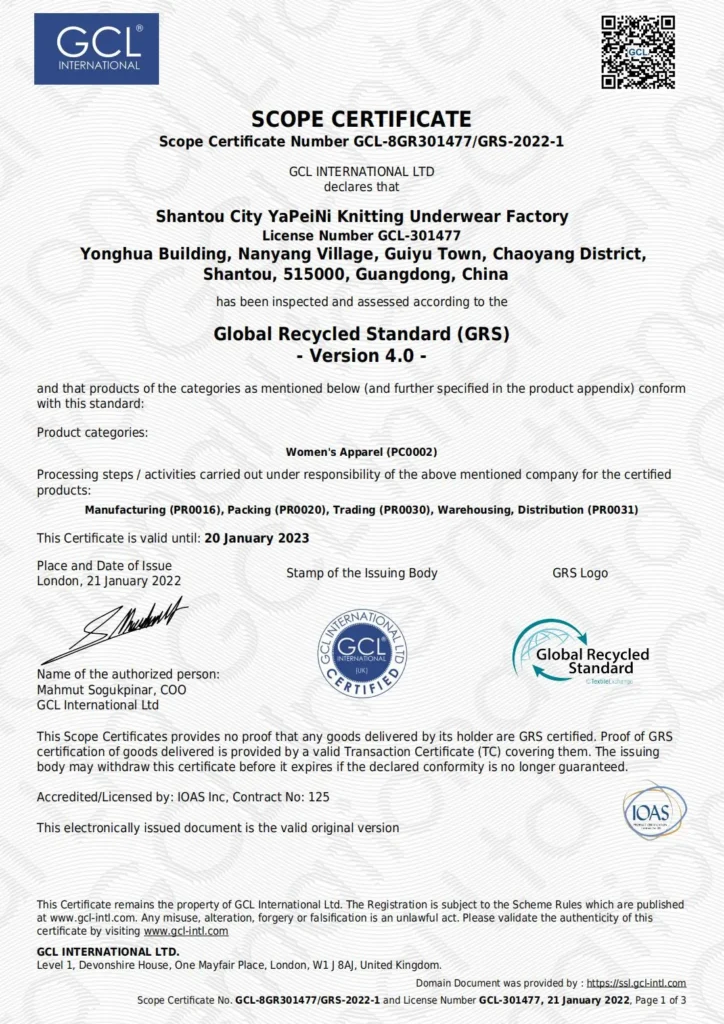

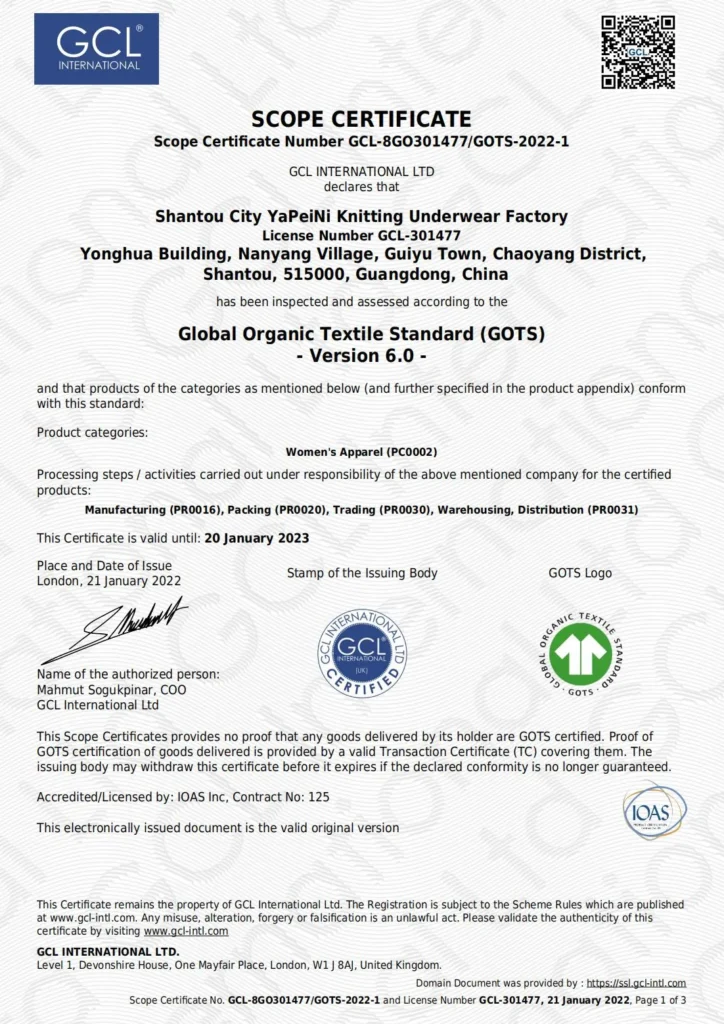

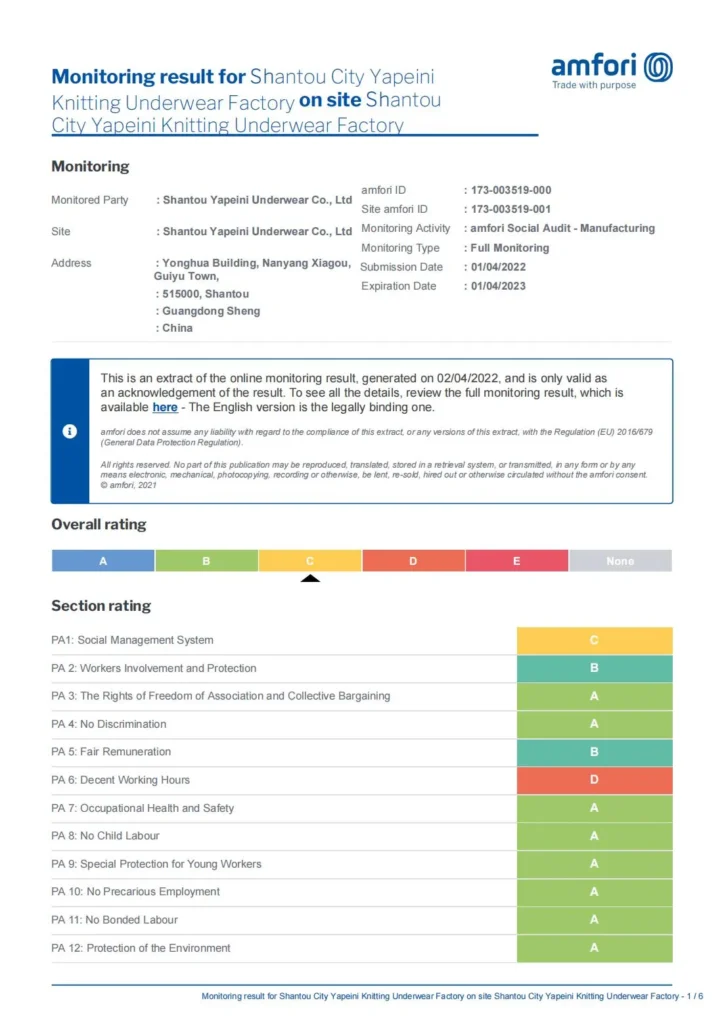

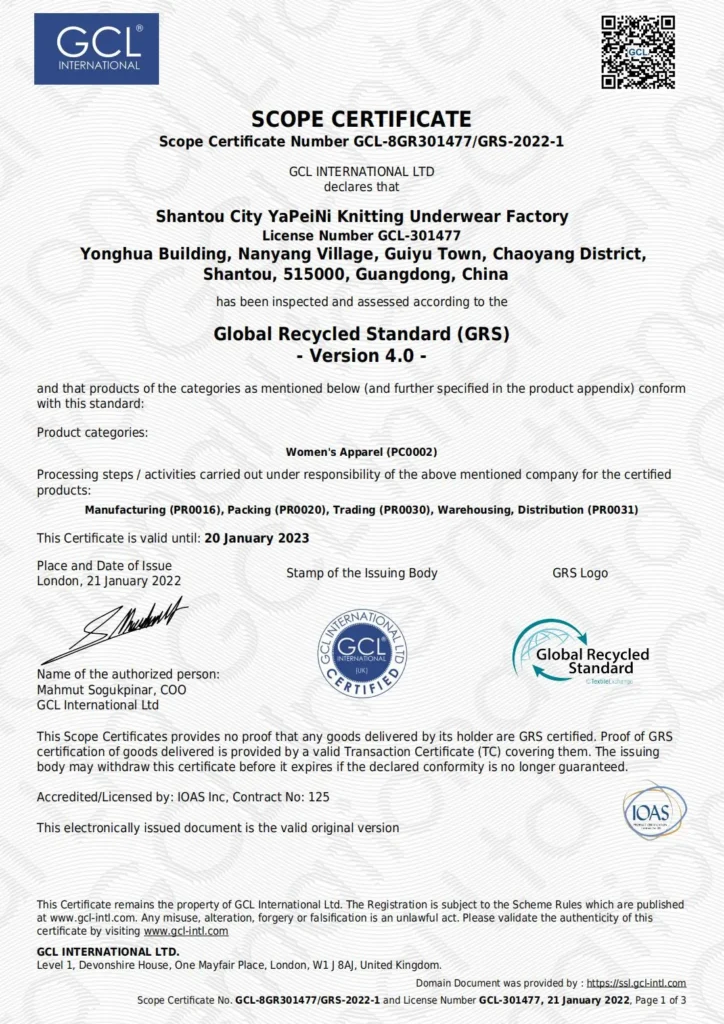

Our Featured Certifications

We’ve dedicated three years to developing truly reliable women underwear—backed by 20+ patents and trusted eco-certifications like OEKO-TEX and GOTS—for comfort, confidence, and sustainability.

Our Cooperated Partners

We’ve sourced period underwear from several factories before, but none matched this supplier’s level of responsiveness and product reliability. Our customers love the fit and leakproof function.

Emily Zhang

Purchasing Manager

Liam Carter

Brand Director

Working with them was a game-changer. Their team helped us fine-tune sizing and materials for our European market, and the certifications (like OEKO-TEX and GRS) gave us a strong edge with eco-conscious retailers.

Sophie Dubois

Product Manager